Edit Content

The No.1 Energy Saving Equipment for ice rinks

Eliminate the need for hot water when building and resurfacing the ice.

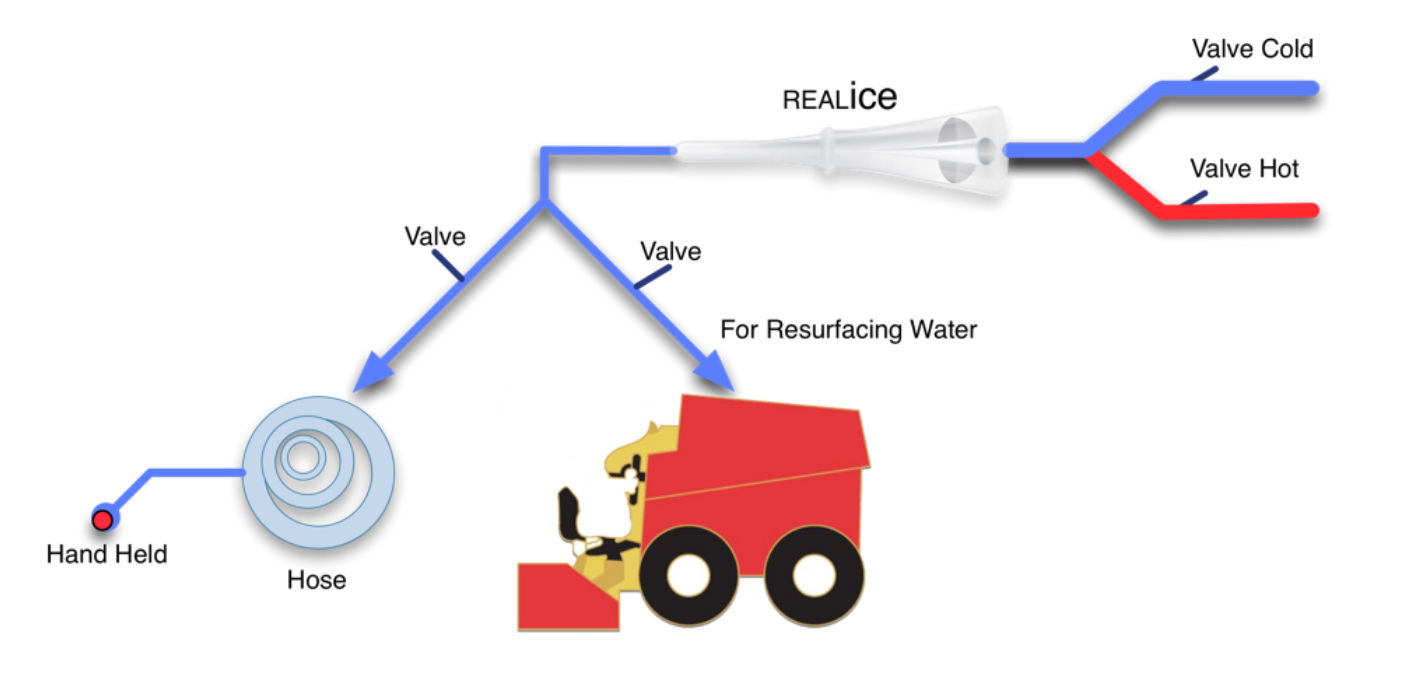

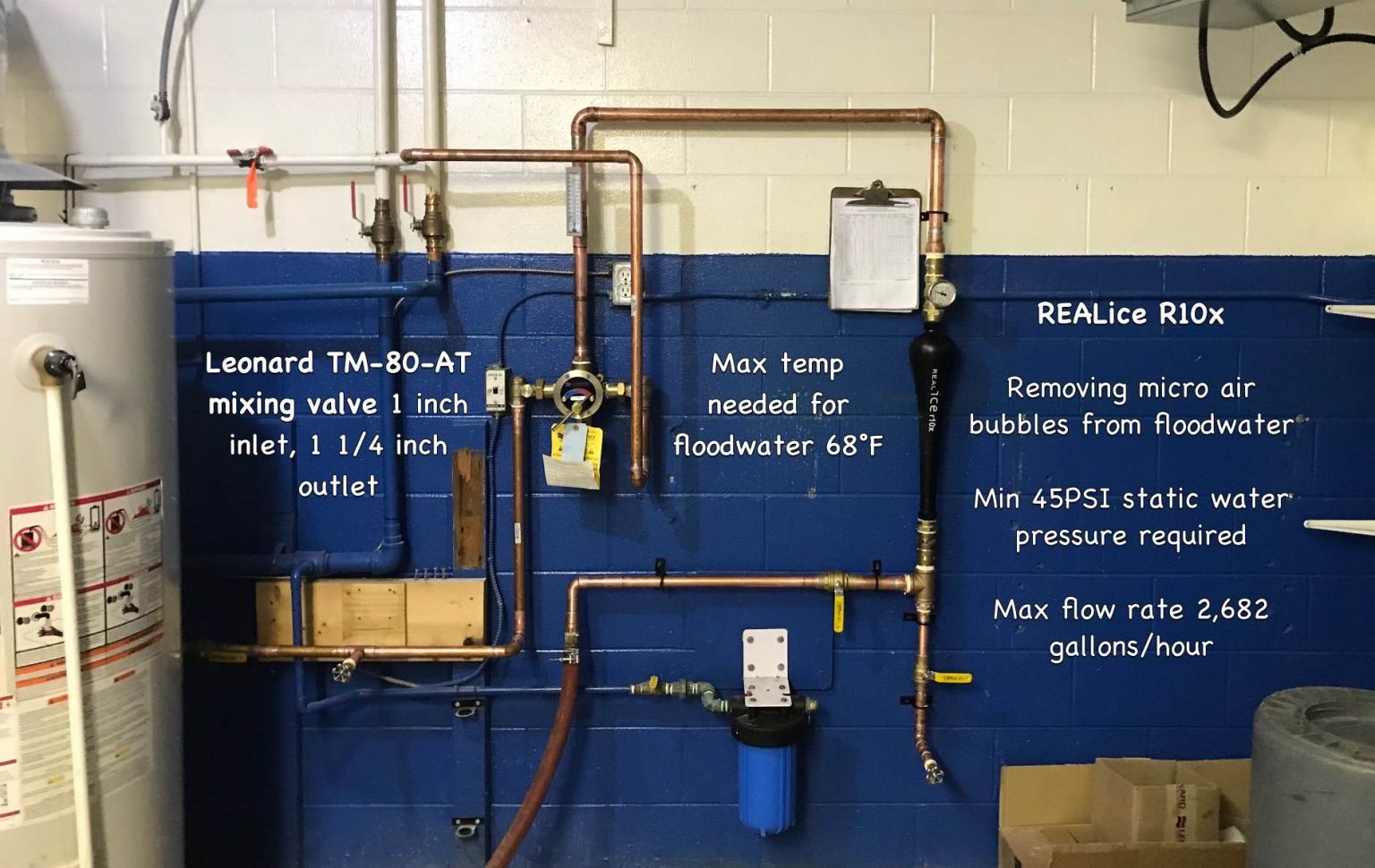

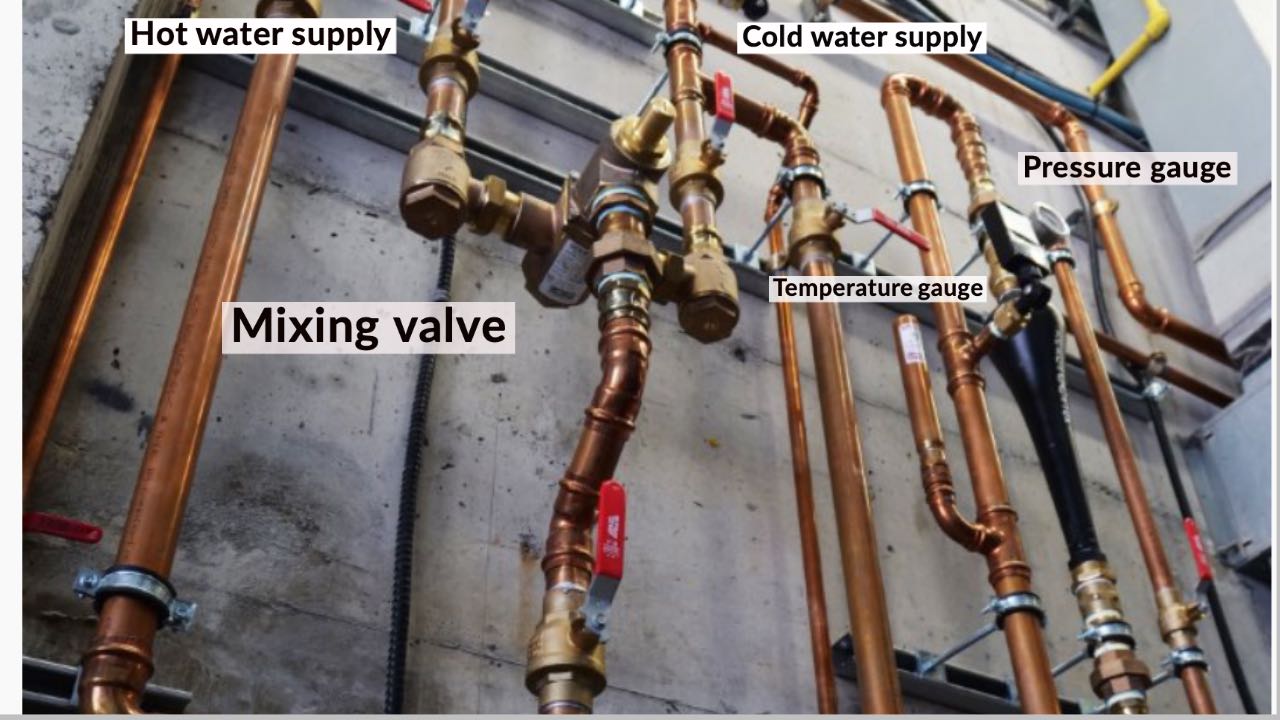

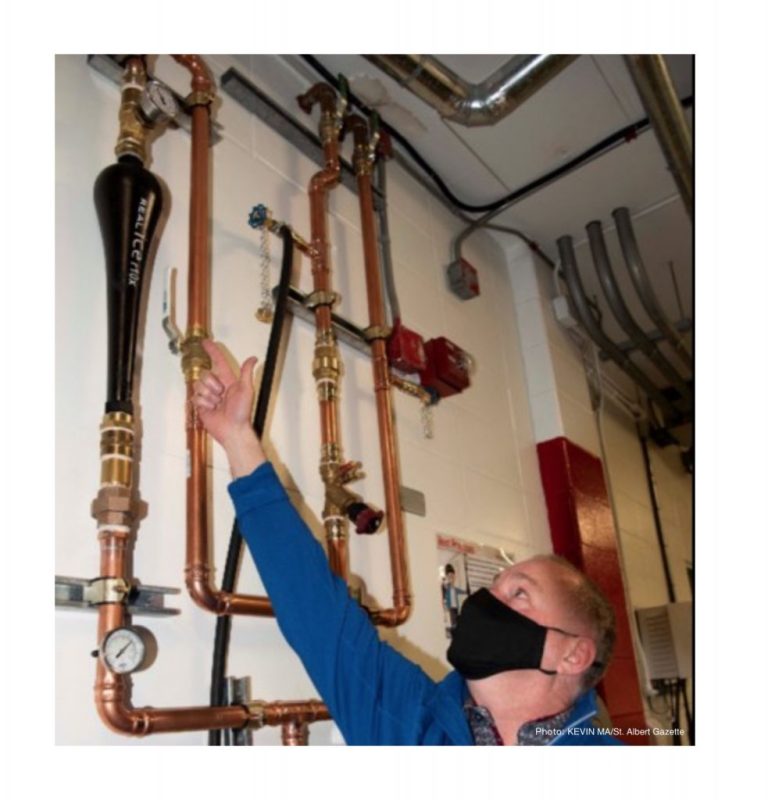

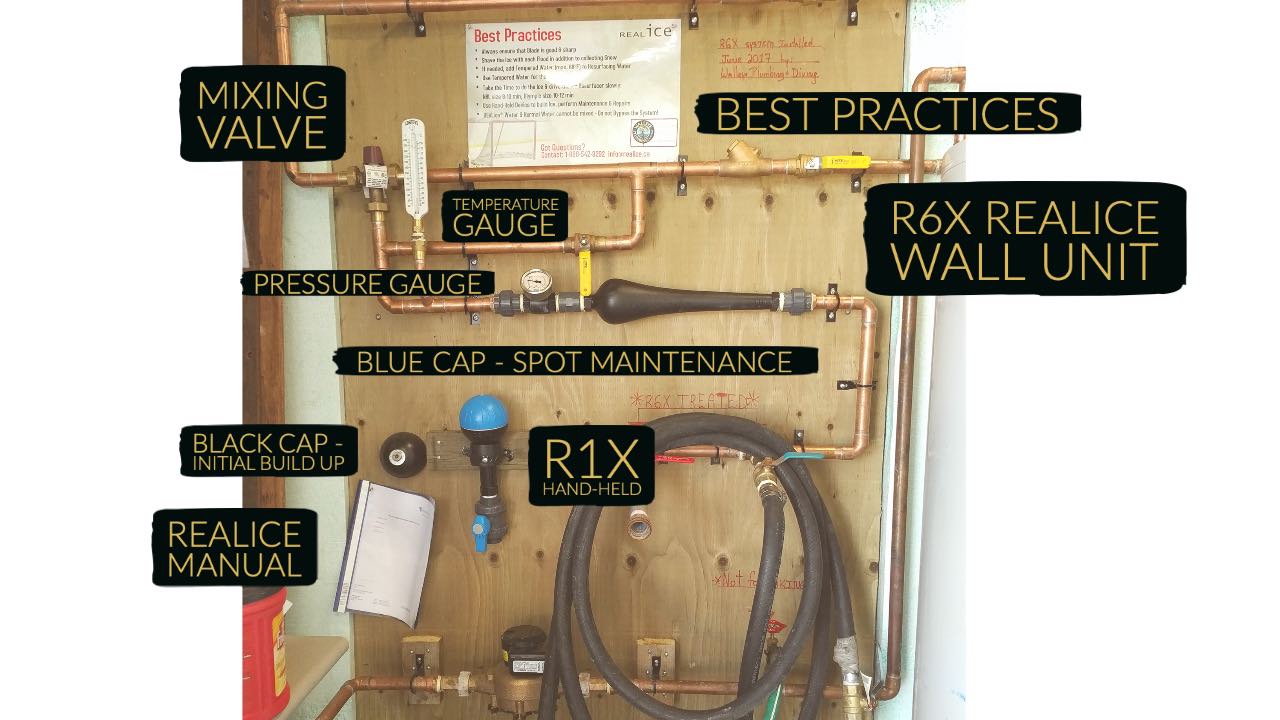

The REALice device forces the water to create an ordered Vortex movement inside the unit to separate the air bubbles from the water and crystalizes the lime particles. These changes created inside the REALice unit eliminates the need to use hot water to build or resurface the ice.

If you’d like to receive an estimate of your energy savings & ROI, take 2 minutes to give us more specifics about your arena by clicking on the “Calculator” button

Our Contact

- 1 Rue d'AnversL-1130 Luxembourg

- +352 26 84 68

- contact@realice.eu

Edit Content

The No.1 Energy Saving Equipment for ice rinks

Eliminate the need for hot water when building and resurfacing the ice.

The REALice device forces the water to create an ordered Vortex movement inside the unit to separate the air bubbles from the water and crystalizes the lime particles. These changes created inside the REALice unit eliminates the need to use hot water to build or resurface the ice.

If you’d like to receive an estimate of your energy savings & ROI, take 2 minutes to give us more specifics about your arena by clicking on the “Calculator” button

Our Contact

- 1 Rue d'AnversL-1130 Luxembourg

- +352 26 84 68

- contact@realice.eu